Improving the sustainability of electric vehicle batteries at all stages of their life cycle. This is the challenge that the partners involved in the Flagship project CircuBAT, supported by Innosuisse, have set themselves. The aim is to reduce the ecological footprint of automotive Lithium-ion (Li-ion) batteries throughout their life stages by creating a circular business model.

The share of electric vehicle sales has been increasing in recent years, and this trend is expected to continue. Switzerland is set to align itself with the European Union, which has decided to ban the sale of petrol vehicles from 2035. Many challenges must be overcome in order to meet this deadline, particularly in terms of sustainability. “Lithium-ion (Li-ion) batteries are not yet sustainable, and their production still relies on raw materials, some of them rated as critical, the extraction of which is problematic,” says Professor Andrea Vezzini of the Bern University of Applied Sciences, who spearheads the CircuBAT project.

The stages of a battery’s life cycle explained

The CircuBAT Flagship project brings together 31 partners from Swiss industry and academia. With each partner working on their own sub-project, their aim is to optimise each stage of a battery's value chain – from creating models that can be repaired and managing them more efficiently to the dismantling and the reuse of components.

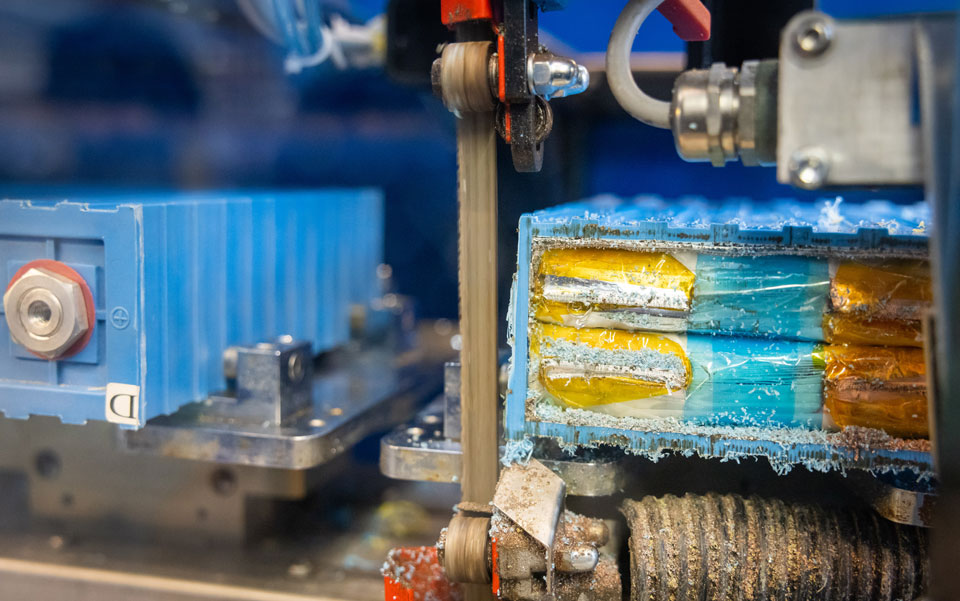

Before a battery can be recycled, its various parts are dismantled. “The aim is to separate the components in order to access the cell components without destroying them,” explains Christian Ochsenbein, head of the Swiss Battery Technology Center. “Today, this process is done by hand, which is very labour-intensive, time-consuming, and dangerous. We are therefore working to develop automation methods with the help of robots.” This step, within the project should also provide manufacturers with guidance so that they can build batteries that are optimised for repair and disassembly.

Current recycling methods are energy-intensive and only recover a small proportion of the materials in a battery. Another step in the project is to improve the process of recovering materials. “We open up the battery cells to recover the main components. The battery's active materials are then separated in a water bath. This means that materials such as copper, aluminium, and their corresponding active material containing lithium, manganese, nickel, graphite, and cobalt can be recovered and either resold or used to produce new batteries,” explains Olivier Groux, Head of Battery Recycling at KYBURZ AG. This process is being developed in close cooperation with EMPA, where the researchers are handling the purification and regeneration of the materials. “Our aim is to recover active material particles, including metal oxides and graphite, and restoring them to their original structure and thus ensuring that quality materials are being reused for new battery manufacturing,” adds Dr. Nora Bartolomé, researcher at EMPA.

Automotive batteries currently have an average lifespan of about ten years in their first life. These batteries often have a remaining storage capacity of 80% of their initial capacity and therefore can be used for many years as storage batteries in the electricity grid, for example for solar or hydropower. “A battery ageing model is thus developed to allow a quick and cost-conscious decision to be made as to whether and when a battery should be removed from its first use and switched to its second use or whether it should be recycled immediately,” explains Andrea Vezzini. Data from this process is analysed and used to develop models to describe battery ageing based on big data and machine learning.

Towards greater sustainability

“CircuBAT is unique in its systemic approach to innovation. Our aim is to find optimised solutions for the Swiss market while taking into account international developments,” explains Vezzini. Research began in 2022 and progress is good. “We installed our first demo of a second-life storage system at the Swiss Bike Park site and were able to refurbish a ten-year-old electric truck to study the behaviour of its batteries beyond their typical initial lifetime. The various stages and the work of all project partners should, in the long term, make it possible to set up a complete system for the recovery of used batteries and thus make electric mobility more sustainable.

Last modification 11.12.2023