Lausanne start-up hopes to help industry switch to solar heating

Industry is responsible for nearly one third of the world’s energy consumption, and three quarters of this is attributable to process heat. Instead of using fossil fuels, it is also possible to produce this heat sustainably: through solar thermal energy. The technology of concentrating solar collectors can be exploited to make more efficient use of solar heat.

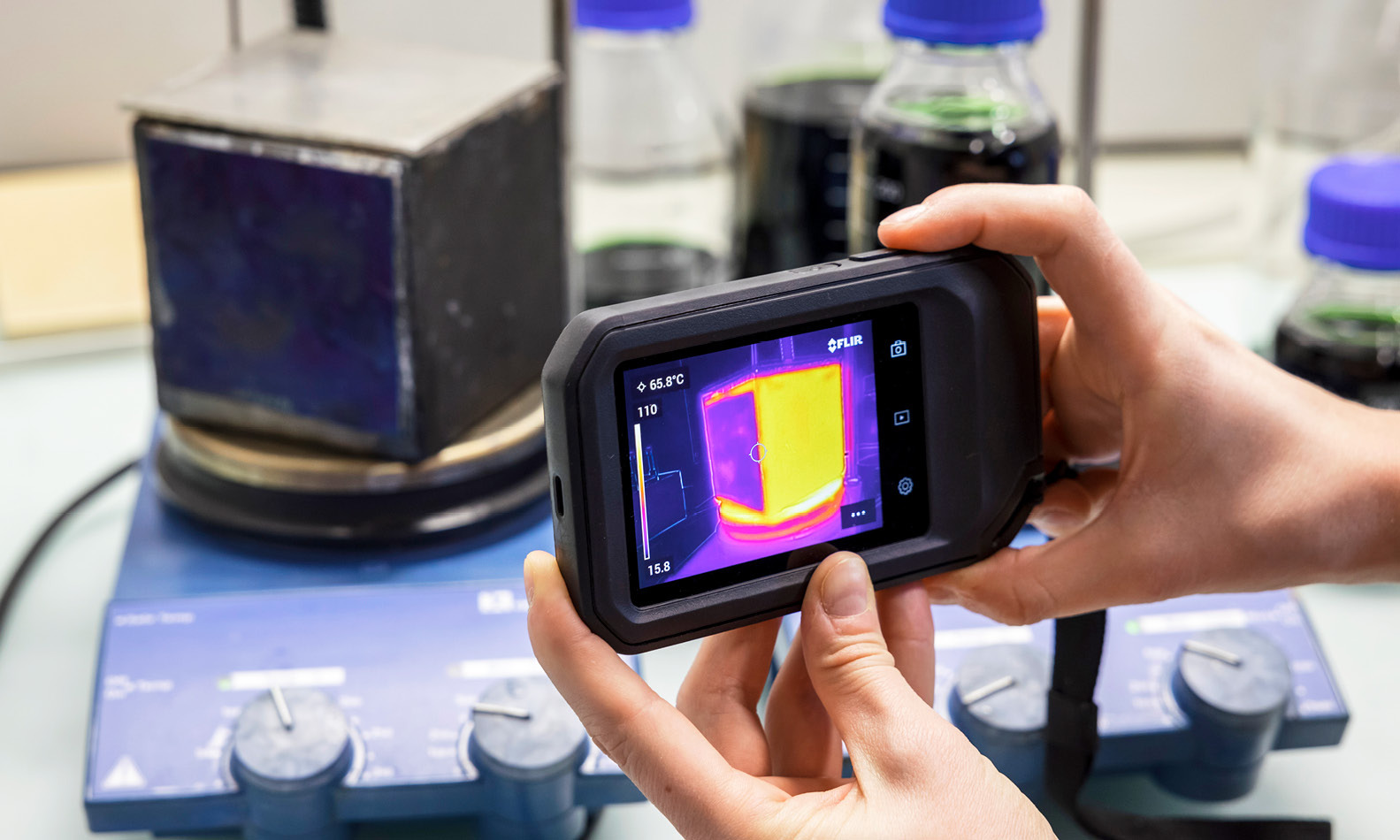

Concentrating collectors use mirrors or lenses to concentrate solar radiation onto a receiver: this is a tube through which a liquid flows, such as water or oil. The liquid is heated by the concentrated solar radiation and transported through the tubes to the consumer, where it releases the heat.

The receiver tube is the key component of the solar collector. Thanks to its special coating, this tube can reach extremely high temperatures, which are required for industrial processes. But conventional coatings oxidise and decompose at high temperatures in the air, lose efficiency and then need to be replaced, resulting in high maintenance costs. Moreover, they are often manufactured using dangerous chemicals.

Efficient and cost-effective coatings from Lausanne

Lausanne-based start-up Solaxer has developed a special coating in an EPFL laboratory led by Andreas Schüler that increases the efficiency of the receivers and that does not oxidise, even at temperatures of up to 400 degrees. Solaxer was founded in early 2023 by two researchers from the Swiss Federal Institute of Technology Lausanne (EPFL), Anna Krammer and Maxime Lagier.

“Even though everyone is talking about electricity at the moment, heat is unfortunately still somewhat on the back burner,” says Anna Krammer. The expert in thin coatings and her business partner aim to become the leading European supplier of high-quality solar receivers. “We’re hoping to help the industry reduce its dependency on fossil fuels. Thanks to our cost-effective manufacturing process, our receivers are competitive worldwide,” says Anna Krammer.

For its coating, Solaxer uses black spinel – an oxide mineral that is also known for being a durable gemstone. The material can withstand higher temperatures than conventional coatings. “For solar thermal systems in industry, you need a heat-resistant material that will last.” The coating is transparent when applied to the tube. Once heated, the material becomes jet black and able to absorb solar energy extremely effectively.

“Thanks to the support from BRIDGE, we had enough time to prepare the research results in a way that would convince investors of our product.”

Anna Krammer

Co-founder of start-up Solaxer

Research results for founding a start-up thanks to support from BRIDGE

For the scientific development work for start-up Solaxer, Anna Krammer was able to count on support provided as part of the BRIDGE programme. BRIDGE is a joint support offering from Innosuisse and the Swiss National Science Foundation. The funding from BRIDGE covered Anna Krammer’s salary, but also funds that the start-up could use to build its first pilot: a machine for the production of coated receiver tubes. “Thanks to the support from BRIDGE, we had enough time to prepare the research results in a way that would convince investors of our product.” The Solaxer coating is protected by a European patent.

With the first prototype, the two start-up founders were able to produce tubes that were up to two metres in length. A second prototype, which has been in operation since the beginning of 2023, allows tubes up to three metres in length to be produced in one piece. “This is not yet industrial production, but it will allow us to produce receiver tubes with a total length of up to 5,000 meters per year.”

This gives the start-up new opportunities to engage with customers. Solar thermal systems are attractive options for manufacturers of beverages, food, textiles or paper, for example, as well as for the pharmaceutical industry. “One of our customers has already shown interest in six-metre-long pieces.” After all, the fewer tubes that ultimately have to be connected to one another, the more efficient the solar thermal system will be.

Anna and Maxime also attended Innosuisse Start-up Training at the EPFL: “Neither of us knew all that much about the economic aspects. The course was intensive and very helpful for us. After the course, we immediately gave our first pitch, which acted as a catalyst. We met a lot of important people and realised how important it is to conduct interviews.”

Knowledge transfer: straight from university into industry

Anna Krammer has an educational background in chemical engineering and materials science. A native of Romania, she studied in France and Germany as part of the Erasmus programme before coming to the EPFL as a research intern, where she earned her PhD and continued her work as a postdoctoral researcher.

Following on from her doctoral thesis, she obtained a scientific mandate with the company Kromatix AG, which came out of the EPFL. A year later, she was employed on a permanent basis as an R&D engineer at the technology company in Romont in the canton of Fribourg, where she still works part-time to this day – in addition to her work for her own start-up Solaxer and for EPFL.

“A creative profession”

The next aim of start-up Solaxer is to equip two to three solar thermal systems with its receiver tubes – for example, for a brewery. “It doesn’t need to be a big system, we would just like to have a demonstration system that will allow us to find investors.”

Anna Krammer knows that there is still a long way to go. But the materials scientist and start-up founder couldn’t imagine a better profession: “I work with exciting materials and am constantly discovering new things, which keeps me on our toes. On top of that: with our work in solar energy, we’re developing something that’s sustainable and working in a field where everyone is here looking for a solution.”

Support from Innosuisse

- BRIDGE – Proof of Concept

- Start-up Training, module 2: Business Concept